Provide concealed anchor device or backing as specified or required in accordance with local building codes before wall is finished. Fasten concealed mounting flanges to anchor device or backing with at least two screws opposing each other in each flange. Snap flange covers over each mounting flange to conceal mounting screws. Concealed anchor devices and mounting screws are not included with Bobrick grab bars and must be specified as an accessory. For Grab Bars with an Intermediate Flange(s), Pull Snap-Flange Covers away from mounting flanges. Place grab bar in desired mounting location. Use intermediate flange as a template to mark location of mounting screws at intermediate flange only. Mark screw locations at the center of the slot in the middle of the double-keyhole shaped mounting holes (2) in the intermediate flange. Remove grab bar from wall. Drive the intermediate flange mounting screws into wall at marked locations. Note: Make sure to leave a space of just over 1/8'' (3.17mm) between the underside of the screw head and the wall. Install grab bar on the wall by placing the round ends of the intermediate flange double-keyhole shaped mounting holes over the mounting screws (2) are located in the middle of the flange slots. Install the mounting screws into the wall at the end flanges and secure tightly. Tighten the mounting screws at the intermediate flange. Press all snap-flange covers into place to conceal mounting flanges. Note: Recommend use of 1/4'' or #14 sheet metal or wood screws to install Intermediate Flange. #12 screws may also be used. Important Notes: 1. Mounting Kits — Bobrick offers a mounting kit for installing grab bars; one Bobrick mounting kit is required for each flange. 2. Grab Bar Fastener — Bobrick offers a grab bar fastening system that secures all Bobrick grab bar series; one Bobrick fastener is required for each flange. Install grab bar without backing in wall requires minimum 5/8" (16mm) thick painted or tiled drywall. 3. Optional Anchor Device — Bobrick grab bar anchor device includes stainless steel machine screws to be used for attaching grab bars to anchors. one Bobrick concealed anchor device is required for each flange. SPECIFICATION: Grab bar shall be type-304 stainless steel with satin-finish, slip-resistant surface. Grab bar shall have 18-gauge (1.2mm) wall thickness and 1-1/2" (38mm) outside diameter. Clearance between the grab bar and wall shall be 1-1/2" (38mm). Concealed mounting flanges shall be 11-gauge (3.2mm) thick stainless steel plate, 2" x 3-1/8" (50 x 80mm), and equipped with at least two screw holes for attachment to wall. Flange covers shall be 22 gauge (0.8mm), 3-1/4" (85mm) diameter x 1/2" (13mm) deep, and shall snap over mounting flange to conceal mounting screws and/or WingIt fasteners. Ends of grab bar shall pass through concealed mounting flanges and be heliarc welded to form one structural unit. Grab bar shall comply with accessible design (including ADAAG in the U.S.A.) for structural strength.

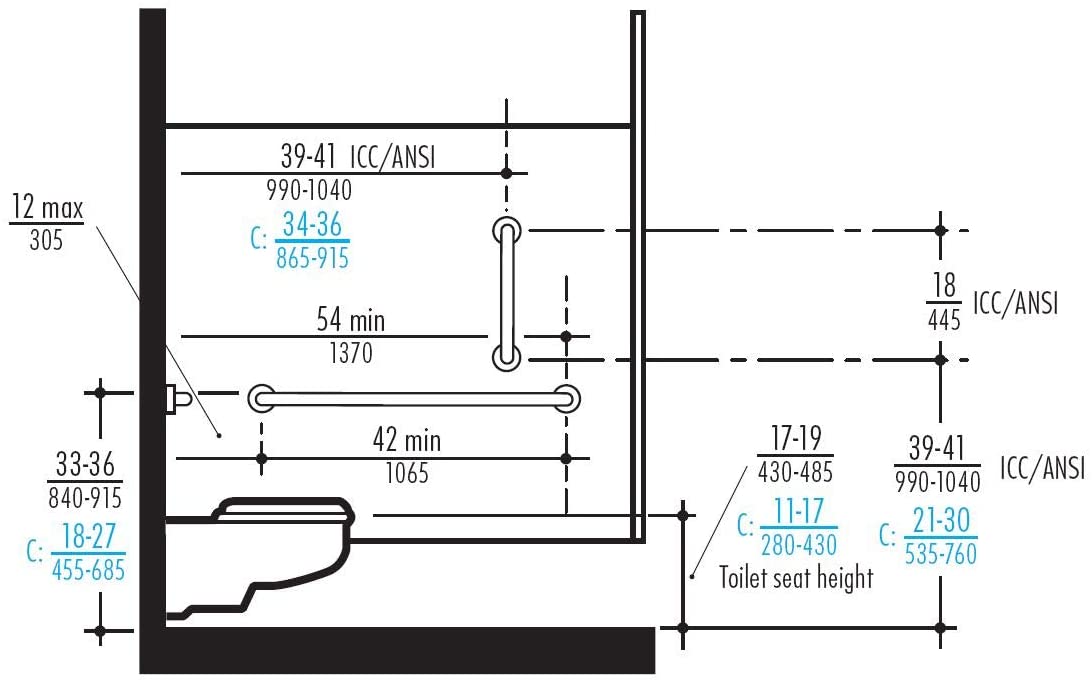

Clearance is distance between finished wall surface and inner edge of tubing. Standard clearance furnished is 1-1/2' (38mm). Required mountain height is 33" to 36" (838 to 914mm) from top of grab bar gripping surface to finish floor. 36" (914mm) horizontal grab bar should be installed on back wall and 42" (1067mm) horizontal grab bar installed on side wall or partition stall. Screws (not furnished).

Safety Warning: Grab bars are no stronger than the anchors and walls to which they are attached and, therefore, must be firmly secured in order to support the loads for which they are intended.

To avoid potential injury, the building owner or maintenance personnel should remove the grab bar from service if the grab bar is not adequately secured to wall or if there is any observed damage to the weld.

Specifications

Grab bars have been designed and tested to withstand a downward pull when properly installed that exceeds HUD, HEW, FHA, VA, and other Federal, State, and local codes, including the Americans with Disabilities Act (ADA). Dimensions are measured from center-line to center-line of tubing, unless noted on grab bar application by circle dimensions which are from center-line of tubing to wall.

NOTE: Grab Bars over 48" in length require a counter-post.